Introduction

Kerplunk! That’s the sound of you dropping your jaw when I drop this fun fact – lathe machines. They’re like the Swiss Army knives of the manufacturing world, decked out with a rotating mechanism that can shape, cut, drill, and even deform objects. Pretty cool, huh? But let’s not get too carried away – there’s a catch!

The Challenge: Workpiece Collisions

Picture this: You’ve got a shiny new lathe machine and a hunk of metal that you’re dying to transform into a masterpiece. You fire up your machine, start turning…and crash! Your workpiece collides with the machine. What gives?

The Solution: Lathe Swing

Enter stage right: Lathe Swing. This character plays a vital role in preventing such catastrophic events. It’s like that friend who tells you if your jeans are too tight before you leave the house. The Lathe Swing is basically a measurement that keeps us in check, ensuring our workpieces are always the perfect fit for our lathes.

Curious about this life-saving (or should I say, lathe-saving) concept? Stick around as we delve into the definition, importance, and all the nitty-gritty details of Lathe Swing. We’ll even discuss how to keep it in mind while choosing your next lathe machine – because nobody wants another kerplunk, right?

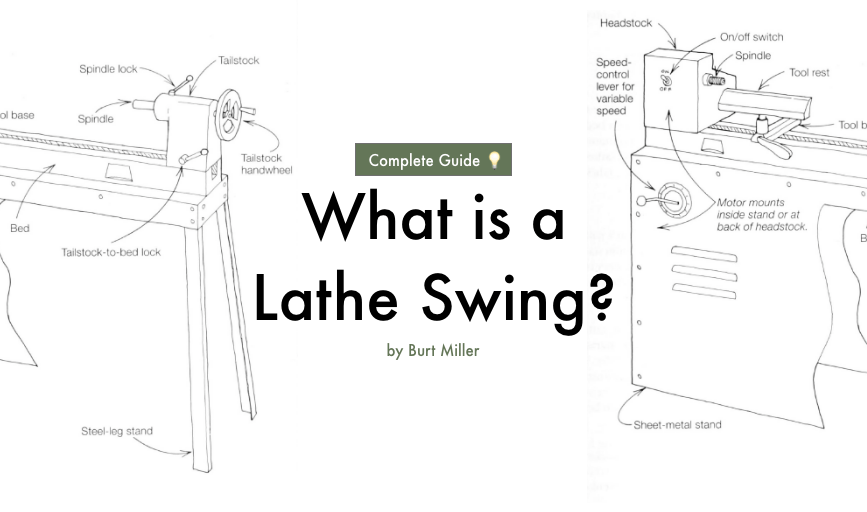

Understanding Lathe Swing: Definition and Significance

When we talk about Lathe Swings, we’re diving into the heart of what makes a lathe tick—or should I say, spin? The term might sound like it’s about the lathe breaking into a jazzy dance routine, but in reality, it’s all about size. Not just any size, though—it’s the maximum diameter of a workpiece that can pirouette on your lathe without smacking into the machine like an overzealous ballerina.

Swing over Bed:

Picture this: your lathe’s bed is like a stage, and Swing over Bed is the star performer’s spotlight diameter. It’s measured from the center of the spindle (where the action happens) to the top of the bed (the stage floor), and then you multiply that number by two because we want the whole spotlight, not just half of it.

This superstar measurement tells you the largest workpiece diameter that can dance on your spindle without bumping into the bed—think of it as ensuring your star doesn’t trip onstage.

Largest Workpiece Diameter on Spindle:

This is essentially what Swing over Bed is about. If you have dreams of machining a majestic oak dowel or a metal rod for your next world-changing invention, making sure it fits within this spotlight without hitting anything is crucial.

Swing over Carriage:

Now, if Swing over Bed is the spotlight’s full diameter, then Swing over Carriage would be how close to the edge of the stage our star can get before they risk falling off. It’s measured from the centerline to above the carriage—the part that carries all your cutting tools—doubling this measurement gives you another limit to how big your workpiece can be before you start playing bumper cars with your tools.

Here’s why these measurements are like rulers at a limbo contest—they set strict limits:

- Without enough swing, your ambitious project could turn into an impromptu game of “Will It Fit?” Spoiler: If it doesn’t fit, nobody wins.

- With ample swing, you’re like a magician pulling out one impressive trick after another. Longer spindles? No problem. Wider platters? Bring them on!

For example, if you’ve got a 7×10 lathe, that first number isn’t just there for good looks—it means you’ve got a 7-inch spotlight for your workpiece to shine without crashing into the bed. And remember, despite what some sneaky labels may suggest, always measure twice so your project doesn’t have to perform an unplanned disappearing act.

In essence, the Definition of Lathe Swing isn’t just some fancy term—it’s like knowing how much room there is for dancing at a party. Too little space and guests feel cramped; too much and it feels empty. For lathes, getting this right means nailing down precisely how big of a bash (or project) you can throw without turning it into an awkward shuffle because something didn’t fit as expected.

So grab those calipers and get measuring because in this world of spinning metal and wood chips flying, knowing your Lathe Swing is like holding onto the secret map where X marks the spot for machining treasure.

How to Calculate the Lathe Swing

Calculating the lathe swing is pretty straightforward:

- Measure the radius: the distance from the center of the spindle to the lathe bed.

- And, then multiply it by 2.

Note: If your lathe has a bed gap, the swing with the gap in place will be greater than the swing without it. Consider this factor if your lathe has a removable gap.

You may also want to consider the different densities of wood you are turning. Down below in the calculator, I have created a way for you to take the above factors into consideration when doing the calculation:

Lathe Swing Calculator

Please note that I have only taken median values of wood types for simplicity sake and have only three options available. If you would like me to add a specific type of wood to the list, shoot me a quick message from the contact page!

The Role of Key Components in Determining Lathe Swing

Diving into the world of lathes is like stepping into a mechanical wonderland where each component plays a part in the grand performance. Now, pay close attention, young grasshopper, because understanding these parts is like knowing your chess pieces before making a move. Let’s break down the critical components that influence the lathe swing.

1. Bed

Picture the bed of a lathe as the Hulk of the machine world – it’s there to provide unyielding support and keep everything stable during operation. In technical terms, the bed is akin to a sturdy backbone for all other components. Here’s why it’s crucial:

- Stability: The bed casting, basically the main supporting casting, is your lathe’s foundation. It needs to be strong because it deals with all the vibrations and forces that occur while you’re chiseling away at your masterpiece.

- Alignment: It ensures that components such as the headstock, tailstock, and carriage stay aligned. You want your cuts to be as straight as an arrow — unless you’re aiming for something more abstract, which is cool, too.

- Precision: A well-made bed prevents flexing under load. Imagine trying to carve a delicate piece only for your machine to start dancing around like it’s doing the jitterbug – not what you need.

So when it comes to swing, think of it this way: if your bed isn’t up to snuff, neither will be your swing measurement or your final product.

2. Carriage

Next up on our lathe tour is the carriage – not Cinderella’s ride to the ball but just as magical in its own right. The carriage has one job: moving those sharp tools back and forth across the workpiece with grace and precision.

- Tool Movement: Those razor-sharp bits need a dance floor to strut their stuff; that’s where the carriage comes in.

- Swing Impact: If your carriage were too bulky or designed without finesse, you’d have less room for larger diameter projects. Think skinny jeans vs. baggy pants – more room can make all the difference.

Remember that swing over carriage? It’s all about how much space you’ve got above this little mover before things get too cozy.

3. Tailstock

Now let’s chat about the tailstock. This isn’t just some piece you can afford to ignore — no sirree! The tailstock is like a trusty sidekick for long workpieces.

- Support: It might not get all the glory, but by supporting one end of your workpiece, it keeps everything steady as she goes.

- Taper Design: That taper isn’t there just for good looks; it’s designed to accommodate different types of centers or bushings, which can affect how much swing room you’ve got.

And here’s a fun fact: if your tailstock is off even by a smidgeon sideways or height-wise, it can turn your cylindrical dreams into wonky reality shows.

4. Headstock

Last but certainly not least is the headstock, basically the captain of Team Lathe Swing.

- Workpiece Rotation: This component holds onto your workpiece for dear life while it spins around at dizzying speeds.

- Speed Change Gears: They’re like choosing gears on a bicycle; different gears impact how fast or slow things go — but instead of affecting how quickly you tire out, they influence cutting speeds and torque.

The headstock determines how big of an item can go round and round without bonking into anything important — crucial for maintaining that maximum diameter we call swing.

By understanding each role these components play in determining lathe swing — from providing stability to supporting and moving tools and workpieces — you set yourself up for success in selecting and operating a lathe machine with confidence.

Now let’s keep this mechanical symphony

2. Carriage

Who’s up for a ride? Well, it’s not the kind of carriage Cinderella took to the grand ball, but it does play a vital role in the fairytale of turning raw material into beautiful pieces. The carriage on a lathe machine is like the unsung hero of machining operations.

What is a Carriage?

The carriage comprises two main parts: the apron and the saddle. It’s like a horse and rider duo where the saddle (the H-shaped casting) rides along the ways (rails) the bed provides, while the apron contains all the gears and controls.

How Does the Carriage Work?

Now, imagine yourself sculpting a piece of clay on a pottery wheel. Your hands glide smoothly over the rotating clay, shaping it to your will. The carriage in our lathe machine does something similar. It moves along the length of the workpiece during turning operations – guided by those rails provided by our trusty bed (remember from our previous chat?).

The Role of Carriage in ‘Lathe Swing’

But here’s where it gets interesting. The size and position of this carriage directly influence our mysterious entity called ‘lathe swing’. Remember when I mentioned ‘swing over carriage’? That’s right! It refers to the maximum diameter of a workpiece that can rotate over this moving carriage without playing bumper cars with it.

So, in essence, understanding your lathe machine’s carriage is as important as knowing your way around town. It sets boundaries for your workpiece size and ensures you’re able to sculpt your materials just right without any sudden surprises!

3. Tailstock

When it comes to lathes, we can’t forget about the Tailstock. This important part acts as a reliable support for long workpieces, preventing them from wobbling while we work on them.

What does the tailstock do?

The tailstock serves two main purposes:

- It provides stability by counterbalancing the forces generated by the cutting tools. Imagine having someone hold onto the other end of a log while you saw through it—it makes the process much smoother and safer.

- It allows for precise positioning of tools and centers through its tapered design. The taper, known as Taper #2MT (Morse Taper #2), ensures a tight fit for accurate work.

Fun fact: The tapered center drill hole in the tailstock is like hitting a bullseye when you need to drill right in the center of your workpiece. It’s incredibly precise!

With an understanding of how the bed, carriage, and tailstock contribute to a lathe’s performance, you’re well on your way to becoming a lathe expert! Now, let’s move on to the headstock—the control center of our lathe party where all the spinning happens!

4. Headstock

Ah, the headstock – that chunky piece of metal at the end of a lathe that makes you think, “Yep, this machine means business.” Let’s dive into its role and why it’s like the quarterback in a game of metalworking football.

Main Supporting Casting

The headstock clings to life on the bed casting, providing a stable base for all that high-speed spinning action. Its job is not only to be sturdy but also to be precise because nobody wants a wobbly workpiece.

Spindle

Imagine this as the merry-go-round for your workpiece; it’s where all the rotation happens. Just like picking the right horse on a carousel, matching your workpiece with the spindle is key for a smooth ride.

Spindle Speed Change Gears

These gears are like the DJ at a party, controlling the tempo of your workpiece dance. Switching up speeds can turn a slow waltz into a speedy tango. The right speed ensures you don’t end up with a project that looks like it was made in a blender.

The relationship between these components and lathe swing capacity is closer than peanut butter and jelly. Here’s why:

- The size and robustness of the headstock determine what kind of disco ball (also known as your workpiece) can hang without causing chaos.

- The spindle has to play nice with both the size of your material and the swing over the bed, or else you’ll get more vibration than an over-enthusiastic phone on silent mode.

- Changing spindle speeds is essential because too fast or too slow could mean either an unfinished symphony or a catastrophic crescendo in your machining opera.

So yes, the headstock is pretty much the captain of Team Lathe Swing. Without it, we’d just have fancy doorstops instead of beautifully crafted cylindrical masterpieces.

Considering Lathe Swing When Choosing a Machine

So, you’re all set to buy your first lathe machine, but wait! What about the swing capacity? Yes, it’s the elephant in the room that can’t be ignored. Choosing a lathe machine without considering its swing capacity is like buying shoes without checking the size. You wouldn’t want to stuff your feet into tight shoes or let them dance around in oversized ones, would you? It’s pretty much the same concept!

Before you empty your wallet, remember that swing capacity is a critical factor in determining whether a lathe machine can handle your project. It’s like the ‘Goldilocks Zone’ – not too big, not too small, it should be just right.

Let’s look at some factors that can help you pick the perfect machine for your needs:

Matching Swing Capacity with Project Requirements

Every project has different demands and needs. For instance, if you’re looking to craft small objects like pens or chess pieces, a lathe with a smaller swing might suffice. But if you’re planning on turning large bowls or table legs, you’ll need a machine with a larger swing.

Ask yourself: What size are most of my projects going to be? If the majority of your work involves large pieces, don’t skimp on swing size. Remember, having more space never hurts, but less…well, let’s just say it can get pretty cramped!

The Size of Your Workspace

Believe it or not, the size of your workspace also plays a role when choosing a lathe machine. Larger machines require more space – they’re not exactly foldable! So before you bring home a massive piece of machinery that covers half of your garage, think: Do I have enough room for this beast?

Your Budget

Let’s face it. Money talks. The greater the swing capacity, the higher the price tag. So, it’s essential to balance your project requirements with how much you’re willing to spend. Can I afford a machine with a larger swing? If the answer is no, you might have to compromise on size or consider buying a second-hand machine.

Future Needs

Consider your future needs as well. Are you planning to stick with small projects forever? Or do you foresee turning large pieces in the future? Investing in a lathe with a larger swing capacity might seem like overkill now, but it could save you from needing an upgrade down the line.

So there you have it, swing capacity isn’t just another number on the spec sheet. It’s a critical factor that determines what your machine can and can’t do. Don’t be that guy who buys a lathe only to realize that it can’t handle half of his projects. Do your homework, consider the swing, and make an informed choice. After all, better safe than sorry!

Conclusion

Hey, mini-machinist-me, if you’ve stuck with me this far, you’re practically a lathe swing guru now! Remember, the key to not turning your lathe dreams into a nightmare is to match the machine’s swing capacity with the gargantuan size of your ambition—or the actual size of those projects you’re itching to tackle.

Phew! That was a lot of words to write! In case you missed something, here are a few key takeaways from what a lathe swing is:

- Understanding Lathe Swing: Lathe swing refers to the maximum diameter of a workpiece that a lathe can accommodate. It is an important specification to consider when choosing a lathe for your projects.

- Key Components: The bed, carriage, tailstock, and headstock are the key components that determine the lathe swing capacity. Each of these components plays a crucial role in supporting and maneuvering the workpiece.

- Choosing the Right Machine: When selecting a lathe, it is essential to match the swing capacity with your project requirements. Consider factors such as the size of your workspace, budget constraints, and future needs before making a decision.

- Budget Considerations: The larger the swing capacity, the higher the price tag. It is crucial to strike a balance between your project requirements and your budget. If affordability becomes an issue, you may have to compromise on size or explore second-hand options.

- Future Needs: Anticipate your future needs when choosing a lathe. If you plan to work on larger projects down the line, investing in a lathe with a larger swing capacity now can save you from needing an upgrade later.

- Importance of Research: Do your homework and consider the swing capacity carefully before making a purchase. It is essential to avoid buying a lathe that cannot handle the size of your projects. Making an informed choice will ensure you can complete your projects efficiently and effectively. Remember, understanding and considering lathe swing capacity is crucial for turning your lathe dreams into reality.

So go ahead and weigh those project needs against the might of various lathes. And when the chips fly—and trust me, they will—you’ll know you’ve chosen wisely. Keep turning those dreams into reality, one rotation at a time! 🛠️💫

FAQs(Frequently Asked Questions)

Lathe Swing refers to the maximum diameter of a workpiece that can be accommodated on a lathe machine. It is a crucial factor to consider when selecting a lathe for a specific project.

Swing over Bed refers to the maximum diameter of a workpiece that can be accommodated on the lathe machine’s bed. It is an important measurement in determining the capabilities of the lathe for handling larger workpieces.

Swing over Carriage refers to the maximum diameter of a workpiece that can be accommodated on the lathe machine’s carriage. It provides information about the available space for machining operations between the carriage and the spindle.

The tailstock serves two main purposes: It provides stability and support to the workpiece during machining operations, and it can be used for drilling operations by holding drill bits in place.

The carriage moves along the lathe’s bed and holds the cutting tool, allowing it to move across the workpiece for shaping and machining. It plays a critical role in determining the size and shape of the final product.

When choosing a wood lathe, it’s important to consider its swing capacity in relation to your project requirements. Factors such as workspace size, budget, and future needs should also be taken into account to ensure that the chosen machine meets your specific needs.